Why Leading Skincare Brands Are Embracing Pineapple Fiber Cosmetic Bags

The beauty industry is experiencing a remarkable transformation as brands increasingly prioritize sustainable packaging solutions that align with consumer values and regulatory requirements. Among the most exciting developments is the adoption of pineapple fiber materials for cosmetic bags, representing a significant shift toward agricultural waste utilization and circular economy principles. This sustainable packaging revolution isn't just about environmental responsibility – it's about meeting the evolving expectations of discerning buyers who understand that packaging quality reflects brand values. The rise of pineapple leaf fiber (PALF) technology, particularly through innovations like Piñatex, has opened new possibilities for creating premium cosmetic accessories that combine functionality with environmental consciousness. Leading manufacturers like Rivta, established in 1990 with over 30 years of manufacturing experience, have become China's premier creators of eco-responsible cosmetic bags, pioneering the integration of innovative materials like pineapple leather into their product lines. With a 6,000 square meter factory and monthly production capacity of 200,000 pieces, established manufacturers are well-positioned to meet the growing demand for sustainable cosmetic packaging solutions.

The Regulatory Landscape Driving Change

The cosmetics packaging industry faces increasing pressure from both regulatory bodies and consumer demand for sustainable alternatives. Recent legislation across major markets has established clear expectations for packaging waste reduction and material transparency. European Union regulations continue to tighten restrictions on single-use plastics and mandate improved recyclability standards. The Extended Producer Responsibility (EPR) frameworks require brands to take accountability for their packaging throughout its lifecycle. Similarly, various states in the United States have implemented plastic reduction initiatives that directly impact cosmetic packaging choices.

These regulatory pressures create both challenges and opportunities for beauty brands. Companies that proactively adopt sustainable packaging solutions position themselves ahead of compliance deadlines while building competitive advantages. The base material of Piñatex (made from 80% pineapple leaf fiber, 20% PLA) is biodegradable under controlled industry conditions, making it an attractive option for brands seeking to meet emerging biodegradability requirements. Beyond compliance, forward-thinking brands recognize that sustainability credentials increasingly influence purchasing decisions, particularly among professional buyers responsible for product curation and brand partnerships. The ability to demonstrate genuine environmental innovation through packaging choices has become a crucial differentiator in competitive markets.

Material Innovation: From Agricultural Waste to Premium Packaging

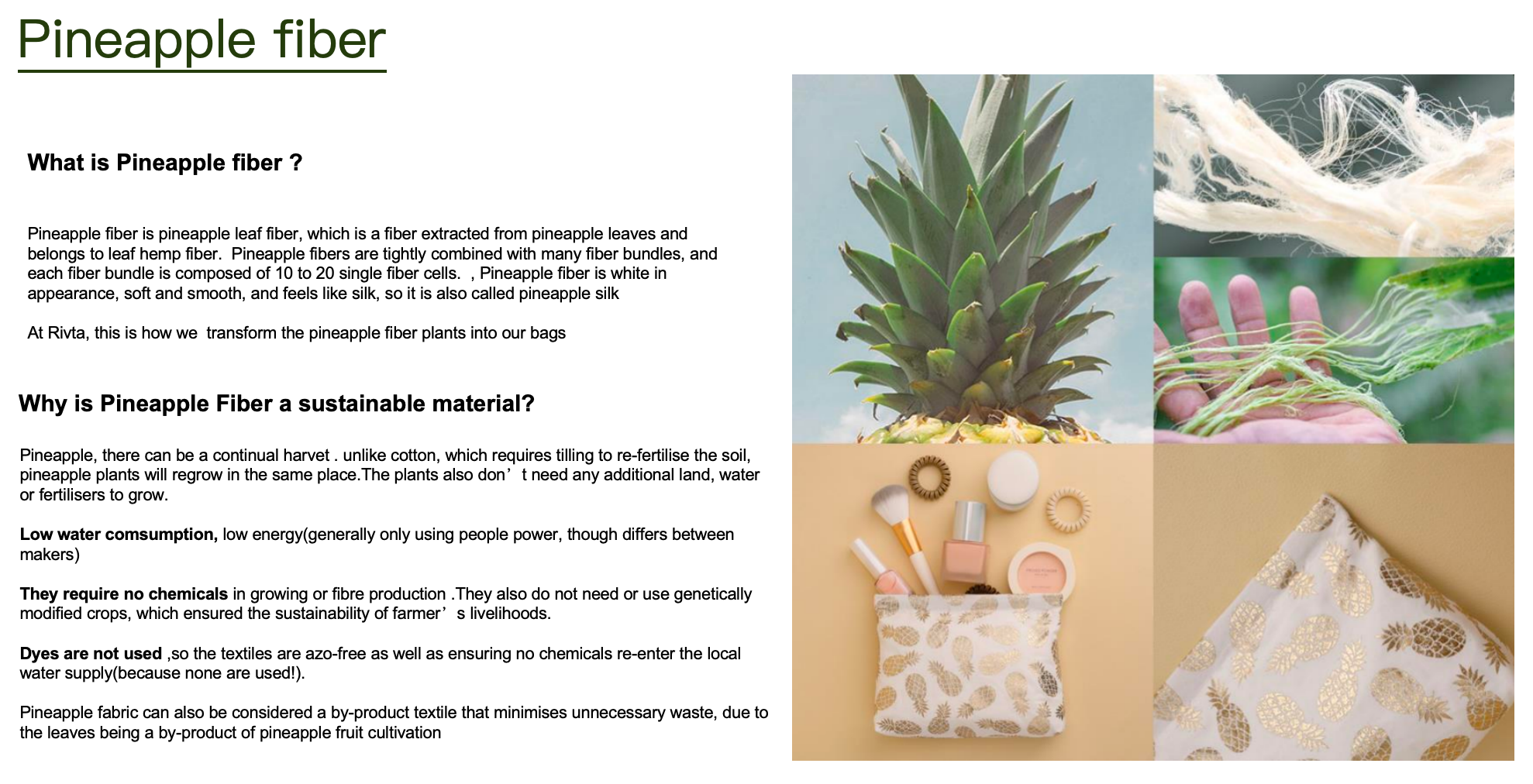

The development of pineapple fiber technology represents a breakthrough in sustainable material science. The leaf fibre, an agricultural waste product, provides the opportunity to build a scalable commercial industry for developing farming communities, with minimal environmental impact. This transformation of agricultural byproducts into high-quality packaging materials exemplifies the circular economy principles that modern brands increasingly embrace.

Traditional pineapple farming generates substantial leaf waste – approximately 40 tons per hectare – that was previously burned or left to decompose. The innovative extraction and processing of these fibers creates value from waste while reducing agricultural environmental impact. A unique proprietary method processes the pineapple leaf fibres to premium textile grade, with no bleaching, no pulping and no dyeing, ensuring that the manufacturing process maintains sustainability throughout.

The resulting material offers impressive performance characteristics that rival traditional packaging options. Pineapple fiber exhibits excellent durability, water resistance, and aesthetic appeal. The natural texture and appearance provide a distinctive premium feel that enhances brand perception while supporting sustainability messaging.

Material Performance Comparison

| Property | Pineapple Fiber | Traditional Synthetic | Cotton Canvas |

|---|---|---|---|

| Durability | High | Very High | Medium |

| Water Resistance | Excellent | Excellent | Poor |

| Biodegradability | Yes (industrial composting) | No | Yes (natural) |

| Carbon Footprint | Low | High | Medium |

| Customization Options | High | Very High | High |

| Cost Efficiency | Competitive | Low | Medium |

The technical properties of pineapple fiber make it particularly suitable for cosmetic bag applications. The material maintains structural integrity under various conditions while offering the flexibility needed for different bag designs and sizes. This versatility enables manufacturers to create products that meet specific brand requirements without compromising performance.

Customization Capabilities and Design Flexibility

Modern cosmetic bag manufacturing demands sophisticated customization capabilities to meet diverse brand requirements. Pineapple fiber materials offer extensive opportunities for personalization while maintaining sustainable production practices. The natural fiber structure accepts various finishing treatments, enabling manufacturers to achieve different textures, colors, and performance enhancements. Brands can specify exact color matching, surface treatments, and functional modifications to create distinctive packaging that reflects their identity.

Advanced printing technologies work effectively with pineapple fiber substrates, allowing for complex graphics, logos, and branding elements. The material's natural texture provides an excellent base for both subtle embossing and bold printed designs. This flexibility enables brands to maintain consistent visual identity across their packaging portfolio while adopting sustainable materials.

Manufacturing processes can accommodate various bag styles, from simple pouches to complex multi-compartment designs. The material's workability allows for precise construction techniques, ensuring that finished products meet the quality standards expected by premium beauty brands.

Customization Options Available

| Feature Category | Available Options | Technical Considerations |

|---|---|---|

| Colors | Natural, Dyed, Printed | Eco-friendly dyes preferred |

| Textures | Smooth, Embossed, Natural | Affects manufacturing complexity |

| Hardware | Metal, Plastic, Bio-based | Must align with sustainability goals |

| Sizes | Mini to Large formats | Material efficiency optimization |

| Closures | Zippers, Magnetic, Drawstring | Durability requirements vary |

| Interior Features | Pockets, Dividers, Elastic bands | Adds functional value |

The customization process typically involves collaborative design development, where manufacturers work closely with brands to optimize both aesthetic and functional requirements. This partnership approach ensures that the final products effectively represent brand values while maximizing material efficiency and production sustainability.

Industry Adaptability and Market Positioning

The adoption of pineapple fiber cosmetic bags reflects broader industry trends toward sustainable luxury and conscious consumption. Beauty brands across various market segments are discovering that sustainable packaging enhances rather than compromises their market positioning.

Premium brands particularly benefit from pineapple fiber packaging because it reinforces their commitment to quality and innovation. The unique origin story of agricultural waste transformation resonates with consumers who value both luxury and sustainability. This narrative creates emotional connections that strengthen brand loyalty and justify premium pricing.

Mid-market brands find pineapple fiber packaging offers competitive differentiation while meeting increasing consumer expectations for environmental responsibility. The material's premium appearance allows these brands to elevate their perceived value without significantly increasing production costs.

The growing acceptance of alternative materials in beauty packaging has created market conditions favorable to pineapple fiber adoption. Major industry players have demonstrated that sustainable materials can maintain product integrity while supporting brand messaging. Their clients include Samsung, Puma, Porsche, BMW, Mercedez Benz, indicating broad acceptance across industries concerned with premium quality and sustainability.

Consumer research consistently shows increasing willingness to pay premium prices for sustainable packaging, particularly among demographic groups that represent key beauty market segments. Professional buyers understand this trend and actively seek suppliers who can provide innovative sustainable solutions that align with their brand strategies.

Manufacturing Excellence and Quality Assurance

Successful implementation of pineapple fiber cosmetic bags requires manufacturing partnerships with companies that possess both technical capabilities and sustainable production practices. The complexity of working with innovative materials demands experienced manufacturers who understand the details of fiber processing and bag construction.

Rivta exemplifies this manufacturing excellence, having grown into one of China's leading creators of eco-responsible cosmetic bags since 1990. Based in Dongguan with comprehensive certifications including BSCI, SEDEX, and ISO9001, Rivta demonstrates the quality standards and ethical practices essential for sustainable material processing. Their experience with innovative materials extends beyond traditional options to include pineapple leather, apple leather, cactus leather, and other cutting-edge sustainable alternatives.

Quality assurance processes must address the unique characteristics of pineapple fiber while ensuring consistent performance across production runs. This includes testing for durability, color fastness, water resistance, and dimensional stability under various environmental conditions. Established manufacturers with decades of experience, like Rivta's 30+ years in the industry, bring crucial knowledge about material behavior and processing optimization.

Manufacturing certifications play a crucial role in establishing credibility and ensuring compliance with brand requirements. BSCI, SEDEX, and ISO9001 certifications demonstrate commitment to social responsibility, ethical practices, and quality management systems. These credentials are particularly important for brands with stringent supplier requirements and corporate responsibility commitments.

Production scalability represents another critical consideration for brands planning significant volume commitments to sustainable packaging. With monthly production capacity of 200,000 pieces and over 120 employees, established manufacturers can demonstrate capacity for consistent quality delivery while maintaining cost-effectiveness across different order sizes.

Quality Standards and Certifications

| Certification | Focus Area | Relevance to Pineapple Fiber Production |

|---|---|---|

| BSCI | Social Compliance | Ensures ethical labor practices |

| SEDEX | Ethical Supply Chain | Validates responsible sourcing |

| ISO9001 | Quality Management | Guarantees consistent production standards |

| OEKO-TEX | Textile Safety | Confirms absence of harmful substances |

| GOTS | Organic Standards | Supports natural fiber credentials |

| Cradle to Cradle | Circular Economy | Aligns with sustainability goals |

The manufacturing process for pineapple fiber cosmetic bags involves several critical stages, each requiring specific expertise and quality controls. Fiber preparation, material processing, cutting, sewing, and finishing all demand attention to detail and understanding of the material's unique properties. Rivta's comprehensive approach to sustainable material processing includes not only pineapple leather but also innovations in apple leather, cactus leather, and other bio-based alternatives, providing brands with diverse options for eco-friendly packaging solutions.

Environmental Impact and Lifecycle Benefits

The environmental advantages of pineapple fiber cosmetic bags extend far beyond simple waste reduction. The complete lifecycle of these products demonstrates significant improvements compared to conventional packaging materials across multiple environmental metrics.

Carbon footprint analysis reveals substantial benefits from utilizing agricultural waste that would otherwise decompose or be burned, releasing stored carbon. The processing methods for pineapple fiber require significantly less energy than synthetic material production while avoiding the petroleum-based inputs associated with conventional packaging. Water usage during manufacturing is considerably lower than traditional textile production processes. An enzymatic process is used to remove impurities without using any harmful chemicals; the rest of the process is fully mechanical, minimizing environmental impact during processing while maintaining material quality.

End-of-life considerations are particularly important for cosmetic packaging, where disposal often occurs in residential waste streams. The biodegradability of pineapple fiber materials under appropriate conditions offers clear advantages over synthetic alternatives that persist in landfills or require energy-intensive recycling processes.

The agricultural communities involved in pineapple leaf collection benefit economically from what was previously waste material, creating positive social impact alongside environmental benefits. This aspect particularly appeals to brands emphasizing social responsibility and supply chain sustainability.

Market Trends and Future Outlook

The cosmetic packaging industry continues evolving toward greater sustainability integration, with pineapple fiber representing one of several innovative material solutions gaining market traction. Industry analysts project continued growth in demand for alternative packaging materials as regulatory requirements tighten and consumer preferences shift.

Technological advances in fiber processing and material engineering are expected to further improve the performance characteristics of pineapple fiber products while reducing production costs. These developments will likely expand the range of applications and increase adoption across different market segments.

Brand partnerships and collaborative development projects are accelerating innovation in sustainable packaging solutions. The success of early adopters creates demonstration effects that encourage broader industry adoption while driving continued material improvements.

Investment in sustainable packaging infrastructure is increasing globally, with both private companies and government initiatives supporting development of alternative material supply chains. This trend suggests that availability and cost-effectiveness of pineapple fiber materials will continue improving.

Consumer education about sustainable packaging benefits is expanding awareness and acceptance of alternative materials. As understanding grows regarding the environmental impact of packaging choices, demand for innovative solutions like pineapple fiber cosmetic bags is expected to increase substantially.

Strategic Implementation Considerations

Beauty brands considering pineapple fiber cosmetic bags should develop comprehensive implementation strategies that address both immediate needs and long-term sustainability goals. This process begins with thorough assessment of current packaging requirements and identification of products suitable for sustainable material substitution.

Supplier selection requires careful evaluation of manufacturing capabilities, quality systems, and sustainability credentials. The ideal manufacturing partner combines technical expertise with genuine commitment to environmental responsibility and social compliance standards. Companies like Rivta, with their 30+ years of experience and comprehensive certifications, represent the type of established partner that can successfully navigate the complexities of sustainable material implementation while maintaining production efficiency and quality standards.

Consumer communication strategies should emphasize the innovation and quality aspects of pineapple fiber materials while explaining the environmental benefits in accessible terms. The unique story of agricultural waste transformation provides compelling content for brand messaging and marketing campaigns. Brands working with experienced manufacturers can leverage their supplier's expertise in multiple sustainable materials – from pineapple leather to apple leather and beyond – to create comprehensive sustainability narratives.

Supply chain integration may require adjustments to ordering processes, inventory management, and quality assurance procedures. Brands should work closely with manufacturers to optimize these operational aspects while maintaining production efficiency. Established manufacturers with proven track records in sustainable material processing can provide valuable guidance during this transition period.

Cost analysis should consider total cost of ownership rather than simple unit pricing, including factors such as brand differentiation value, consumer appeal, and regulatory compliance benefits. Many brands find that the comprehensive benefits of sustainable packaging justify any incremental costs, particularly when working with manufacturers who can optimize production efficiency through economies of scale.

Conclusion: Leading the Sustainable Packaging Revolution

The adoption of pineapple fiber cosmetic bags represents more than a packaging decision – it demonstrates leadership in the sustainable beauty movement. Brands that embrace these innovative materials position themselves at the forefront of industry transformation while meeting the evolving expectations of environmentally conscious consumers.

The combination of environmental benefits, performance capabilities, and customization options makes pineapple fiber an attractive choice for beauty brands across various market segments. As regulatory requirements continue tightening and consumer awareness grows, early adoption of sustainable packaging solutions provides competitive advantages that extend beyond simple compliance.

The success of pineapple fiber cosmetic bags depends on partnerships with experienced manufacturers who understand both the technical requirements and sustainability imperatives driving industry change. Companies like Rivta, with their three decades of manufacturing excellence and commitment to eco-responsible innovation, create opportunities for brands to differentiate themselves while contributing to positive environmental and social impact. Their expertise in processing multiple sustainable materials – including pineapple leather, apple leather, and cactus leather – provides brands with comprehensive solutions for their sustainable packaging needs.

For beauty brands ready to embrace the future of sustainable packaging, pineapple fiber cosmetic bags offer a proven path forward that combines innovation, quality, and environmental responsibility. The technology exists, the market demand is growing, and experienced manufacturers with proper certifications and production capacity are available to support successful implementation.

The question isn't whether sustainable packaging will become standard in the beauty industry – it's whether brands will lead this transformation or follow the pioneers who are already capturing the benefits of innovative materials like pineapple fiber. With established manufacturers like Rivta offering comprehensive sustainable material solutions and the production capacity to meet growing demand, the time for action is now, and the opportunities for brands willing to embrace sustainable packaging innovation continue expanding.

To explore how pineapple fiber cosmetic bags can enhance your brand's sustainability profile while maintaining premium quality standards, consider partnering with experienced manufacturers who combine technical expertise with environmental commitment. Visit www.rivta-factory.com to discover how three decades of manufacturing excellence can support your brand's transition to sustainable packaging solutions.